What are the forms of clothing packaging?

(1) Traditional packaging

Traditional packaging is conventional bag and box packaging, which is usually divided into two forms: inner packaging and outer packaging.

1. inner packaging

Also called small package, it can be made of paper, plastic bag, carton and other materials. The paper bag should be folded properly and the packaging must be firm; the size of the plastic bag and carton packaging should be suitable for the product, and the product should be flat and tight when packed in the plastic bag or carton; Add neutral white backing paper and white cardboard under it to prevent the product from being stained and deformed. Small packages are sometimes packed into plastic bags in units of pieces or sets, and sometimes packed into paper bags or boxes in units of 5 pieces or a dozen.

2. Outer packaging

Also known as large packaging, it can be made of paper boxes, wooden boxes and other materials. The packaging materials should be clean, dry and firm. The carton should be lined with moisture-proof materials that can protect the product, and the contents of the carton should be flat, and the packaging should not be deformed. The lid and bottom of the carton should be tight and firm, and the sealing paper should be pasted up and flat. The size of the inner and outer packaging is suitable, and the outside of the box can be tied tightly with strapping and the buckle is firm. The mark mark of the product is usually printed on the outside of the large package box, and the mark mark must be consistent with the actual content of the package.

(2) Vacuum packaging

Vacuum packaging is a new packaging technology that came out in the 1970s. It is a packaging in which clothing products are placed in airtight packaging containers, and vacuum is applied before sealing, so that the sealed container can reach a predetermined degree of vacuum.

Vacuum packaging first reduces the moisture content of the clothing, then puts the dehumidified clothing into a plastic bag, compresses and evacuates, and finally glues the bag mouth. In this method, the moisture content of the clothing is reduced to a certain level. Therefore, although it is compressed during storage and transportation, it is not easy to produce creases. The vacuum packaging method has the advantages of reducing the shipping volume and weight of the garment, preventing the garment from wrinkling and mildew during the shipping process, and occupying a small storage space.

Generally, products such as maternity and infant health care clothing and medical clothing are mostly vacuum-packaged to ensure that the sterilized clothing products will not be contaminated again during transportation and sales.

(3) Three-dimensional packaging

After ironing and shaping, the surface of the garment is smooth and beautiful, with a strong sense of three-dimensionality. However, after packaging and transportation in the form of a bag or box, wrinkles are often generated, which affects the appearance of the garment. The three-dimensional packaging can prevent the clothing from being squeezed or folded during the entire packaging and transportation process, and always maintain a good and flat appearance, thereby ensuring the appearance quality of the product and increasing the value of the product. But for apparel companies, the investment is relatively large and the transportation cost is relatively high.

Three-dimensional packaging is to hang clothes on a hanger with a plastic bag, and then hoist them in a special packing box with beams, or directly hang the clothes in a container, so three-dimensional packaging is also called hanging. Three-dimensional packaging is mostly used for mid-to-high-end suits and coats. The structure of the three-dimensional packaging box is to adapt to the characteristics of large import and export volume and long transportation period of modern clothing, and hanging clothing containers are widely used. The container is made of aluminum alloy or steel, and many beams and hooks are neatly hung in the box for hanging clothes. The biggest advantage of this packaging and transportation method is that the clothing is not folded, squeezed, or deformed, and the quality is fully guaranteed.

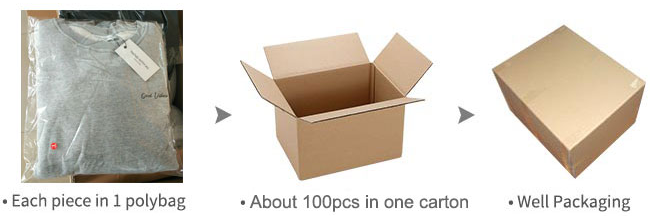

Our normal packing for clothing is each piece shall be packed in a PE ziplock bag, about 100pcs in a carton.

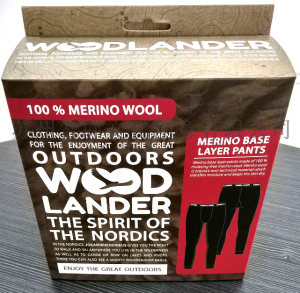

As a professional manufacturer, we can customize packaging according to your requirements, like print your logo on the packahing both of bag and carton. Beiseds, we also can custom print the color box for your packing.