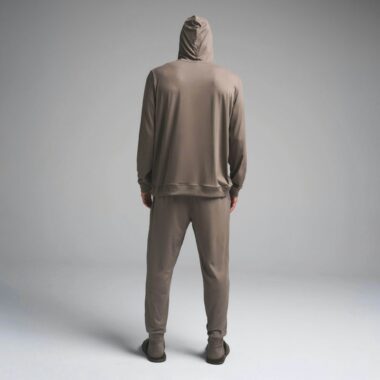

Heavyweight hoodies represent the pinnacle of comfort, structure, and durability. With fabric weights ranging from 400 to 500 GSM, these garments offer not only superior warmth but also a substantial handfeel that defines the luxury and streetwear markets. For designers and sourcing teams, understanding the material science behind heavyweight fleece is essential to achieving the perfect balance of thermal performance and production efficiency.

🧵 1. The GSM Equation: Density vs. Drape

GSM (grams per square meter) determines the thickness and density of a hoodie’s fabric. Standard retail hoodies range from 280–350 GSM, while heavyweight models start at 400 GSM and can reach up to 520 GSM.

However, higher GSM does not always mean better quality—it must be matched with yarn composition and knit density.

-

400–430 GSM: Ideal for cold-weather streetwear; maintains comfort with manageable weight.

-

440–480 GSM: Premium-grade balance between warmth and structure, preferred by export buyers.

-

500 GSM+ fleece: Reserved for luxury markets where the hoodie doubles as outerwear.

Professional heavyweight hoodies suppliers carefully calibrate yarn tension and knitting speed to achieve even density without excessive stiffness, ensuring that the garment drapes naturally while retaining shape.

⚙️ 2. Fabric Composition and Weaving Structure

The strongest and softest heavyweight fleece comes from combed ring-spun cotton blended with polyester for stability.

Common blends:

-

80/20 cotton-polyester: Classic ratio for structural strength.

-

65/35 poly-cotton: Improves shrinkage control for export logistics.

-

Organic cotton/recycled poly: Eco-friendly alternative with soft handfeel.

The inner loopback layer is brushed to create micro-air pockets that trap heat, while the outer face is tightly knitted for durability and print compatibility. This dual-layer construction creates a naturally insulated barrier—keeping the wearer warm without unnecessary bulk.

🧶 3. Shrinkage Control and Pre-Setting

Heavyweight fabrics are prone to dimensional changes after washing due to their density. Factories use pre-setting and tumble stabilization to minimize shrinkage before cutting.

Shrinkage control steps include:

-

Pre-wash & tumble dry at controlled temperature (60°C) to lock fabric dimensions.

-

Relaxation period for yarn tension release before bulk production.

-

Heat-set pressing after garment sewing to stabilize shape.

These procedures maintain length and width variation within ±3%, meeting export-grade quality standards.

🌡️ 4. Thermal Retention: The Warmth Factor

The thermal efficiency of heavyweight hoodies comes from both fiber composition and air retention.

-

Brushed fleece interiors trap air layers for natural insulation.

-

Compact outer weaves prevent cold air penetration.

-

Moisture-regulating finishes ensure comfort during extended wear.

In laboratory tests, 450 GSM fleece showed 20–25% higher thermal retention than midweight alternatives. Some suppliers integrate thermal fleece liners or micro-quilted interlining to enhance insulation for extreme-weather collections.

🧩 5. Construction Techniques for Heavier Fabric

Thicker fabrics require specialized machinery and skilled operators. Key construction adaptations include:

-

Heavy-duty overlock machines with higher needle penetration force.

-

Reinforced seams with 12 SPI (stitches per inch) for long-term durability.

-

Flatlock shoulder joints to prevent bulk at high-tension points.

Factories also employ rib-matching technology, where rib GSM is increased by 10–15% to maintain proportional elasticity against the dense fleece body.

🧪 6. Testing Standards for Quality Assurance

Every heavyweight hoodie batch undergoes technical tests to guarantee reliability:

| Test Type | Purpose | Acceptable Range |

|---|---|---|

| GSM Consistency | Ensures weight accuracy | ±5 GSM tolerance |

| Shrinkage Test | Measures wash stability | ≤3% |

| Pilling Resistance | Surface durability | Grade 4–5 |

| Thermal Retention | Warmth performance | 20% > midweight |

Meeting these standards ensures that the hoodie retains structure and softness even after 50+ wash cycles.

🌿 7. Eco & Sustainable Production Options

Sustainability has become a key selling point in heavyweight apparel. Many factories now offer:

-

Recycled polyester fleece yarns certified by GRS.

-

Organic cotton with GOTS compliance.

-

Low-impact dyeing that reduces water consumption by up to 40%.

These initiatives align with modern brand narratives without compromising the signature density and warmth heavyweight hoodies are known for.

📦 8. Bulk Production and Market Segments

Heavyweight hoodies dominate multiple markets—from fashion retail to outdoor gear. Bulk buyers typically divide usage into three categories:

| Market Segment | Target GSM | Key Attributes |

|---|---|---|

| Streetwear | 430–480 | Structured silhouette, heavy drape |

| Corporate / Teamwear | 400–450 | Durable, uniform warmth |

| Luxury Retail | 480–520 | Sculpted form, dense fleece |

To maintain consistent GSM and quality across seasons, many brands collaborate with established Heavyweight Hoodies Suppliers, who manage controlled sourcing, mill calibration, and long-term material archives.

For distribution and scaling, reliable Hoodies Wholesale networks provide synchronized delivery schedules and inventory planning—ensuring steady flow during seasonal demand peaks.

🏁 Final Thoughts

Heavyweight hoodies are more than garments—they’re engineering statements. Every gram of fabric weight contributes to warmth, structure, and identity. Behind their bold silhouette lies careful calibration of fiber, density, and finishing precision.

By working with experienced heavyweight hoodies suppliers, brands can unlock premium performance and tactile luxury in every piece. From shrinkage control to thermal retention, each detail reflects one principle: comfort built to last.